“Safer for Life” is our motto and the commitment to people’s safety and welfare.

Hornling is the leader in seat belt design & manufacturing. Hornling has had over sixty-year experience of manufacturing safety parts since it was founded in 1959.

At Hornling, we strive to maintain excellence and reliability by implementing “KAIZEN” spirit of improving quality relentlessly. All of Hornling’s products pass the most stringent inspections and tests.

By our vertical integration capability in-house from R&D, mold making, press stamping, plastic injection molding, assembling, testing to local customer service, we provide speedy and complete solutions to our valued customers.

Hornling seat belts are widely used in diverse fields, including Side-By-Side vehicles (Utility, Powersport, Recreation), Turf Equipment, Wheelchair Restraint Systems, Agricultural Machinery, Construction Machinery, Military HUMVEE, Snow Plows, Transit Buses, Emergency Vehicles, Trucks, School Buses, and many other specialty vehicles.

We invest in state-of-the-art technologies, innovate unique designs, and manufacture the safest products for our customers. Hornling’s R&D contributes unprecedented patents which are the best solutions to our customers.

“Mold is the mother of industry - Only perfect mold can produce highest quality products” was the faith of Mr. Lien-Lin Wang, the founder of Hornling, and the motto for everyone in the HORNLING team.

“Exceed Customer’s Expectations” is our guiding principle and it has been deeply rooted at Hornling.

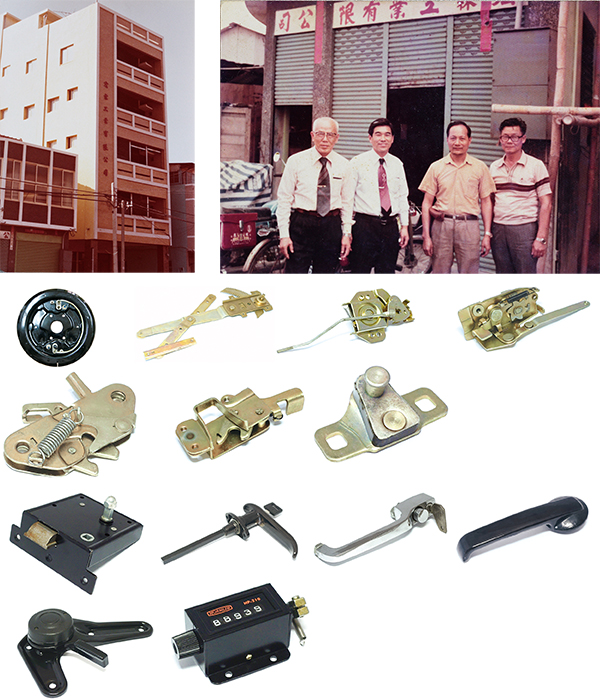

1959

- Mr. Lien Lin Wang and his wife, Mrs. Wang Wong Fong Bai, founded Horn Yi Industry.

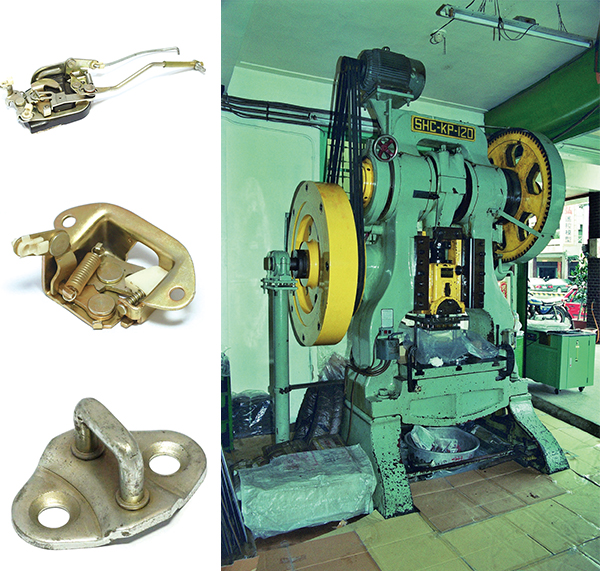

- Manufactured bicycle and motorcycle parts.

1966

- Change company name to Hornling Industrial Inc.

- Started to make auto parts – door striker, door lock, remote, and back lock

1976-1988

- Qualified Tier One Supplier of Taiwan Subaru Automotive.

- Supplied door lock, door latch, remote, striker, window regulator, and brake plate assembly.

- Brake plate assembly and other auto parts were certificated by Fuji Heavy Industrial Ltd.

- Manufactured seat recliner, door lock, outside handle, door hinge, window opener to Sweden, Malaysia, Indonesia, etc.

1989

- Developed HL’s first 3 PT ELR seat belt – HL 610. FMVSS 209 and 302 certificated by SGS USA.

- Started seat belt restraint system business.

2000

- Enhanced R&D to produce diverse restraint systems for different applications.

- ELR retractor for Humvee of USA military, reserved wound ELR retractor for trucks, child seat tighteners & ALR retractors.

2006

- Construction of new headquarters plant was completed.

- Established vertically integrated abilities: mold fabrications, press stamping, plastic injection molding, assembling, and inspections.

2010

- Protect people’s safety everywhere – school bus, transit bus, wheelchair restraint, emergency vehicle, UTV, tractor, mower, etc.

- Developed the first Muddy ELR retractor seat belt of UTV industry to OEM manufacturers – Polaris, Yamaha, Kawasaki, Kubota, Arctic Cat, Honda, and BRP.

2019

- Celebrated Hornling 60th Anniversary.

- Principles deeply rooted in Hornling team: Techniques, Honesty, World class quality, Exceed customer’s expectations.

2020

Continue to strive for product and process excellence, and provide the best solution to our valued customers.

© Copyright Hornling inc., 2023. All Rights Reserved.